Digital networks and advanced production integrate with sustainability

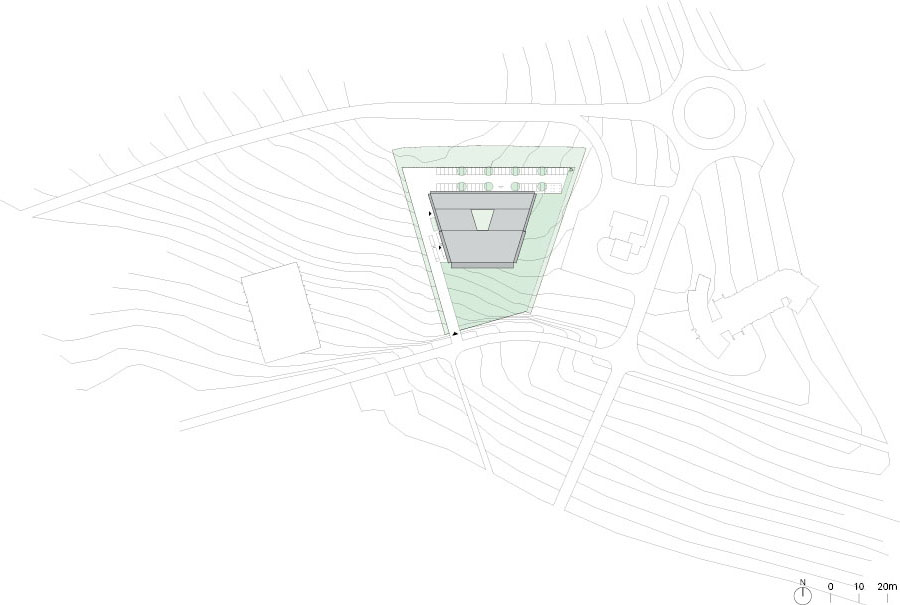

Located in the Gödöllő industrial park on the outskirts of Budapest, Hungary, stands a factory that doubles as a showroom. Operated by the U.S.-based Trumpf company, specialized in precision industrial machine tool and laser technology, the Hungarian branch offers customers a firsthand experience of the entire process—from metal sheet forming and processing to production and delivery. Moreover, it showcases innovations geared toward future industries by building an intelligent factory that leverages digital technology for automated and efficient production—a true smart factory.

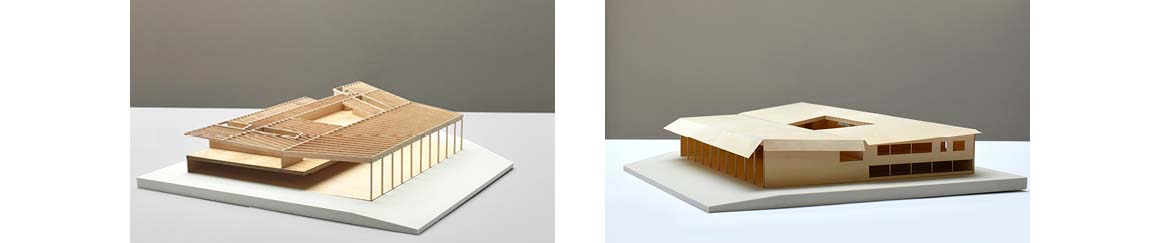

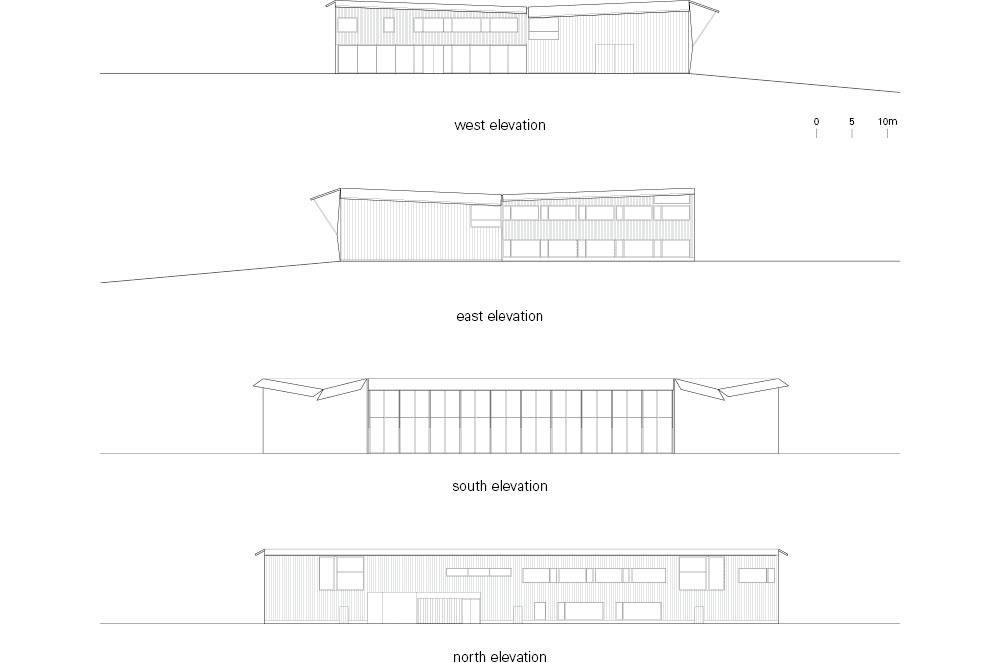

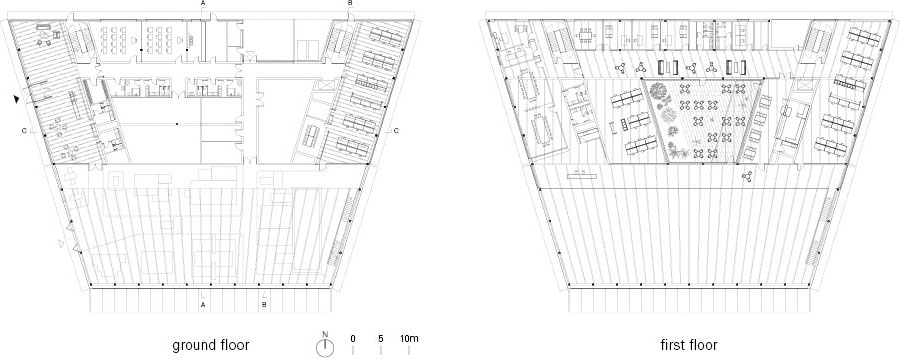

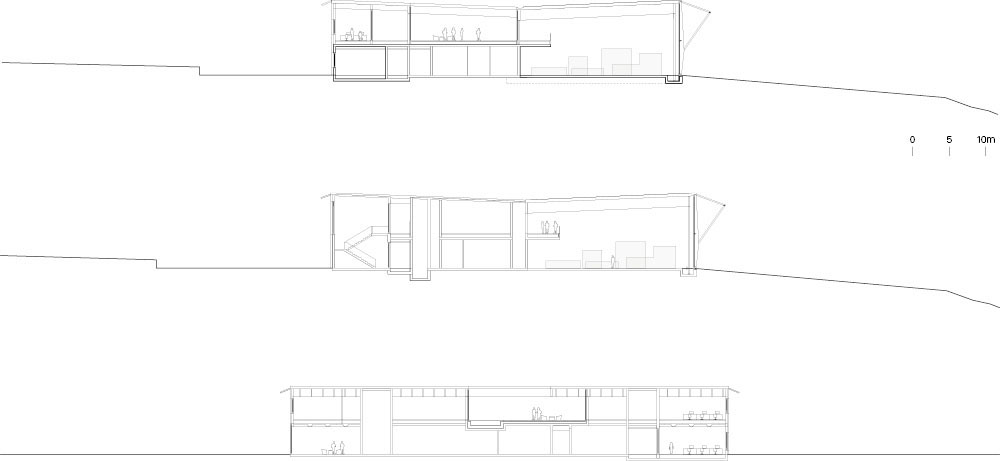

The Trumpf Hungary Smart Factory is designed in a meticulously tailored trapezoidal shape. The southern façade features a high-ceilinged showroom that creates a striking entrance. To the north, offices, lecture rooms, seminar spaces, and storage areas are arranged in a two-story structure. At the center of the building, a courtyard enhances natural light for the café, offices, and meeting rooms. A 20-meter-long catwalk traversing the upper levels provides a view of the production machinery in real-time operation.

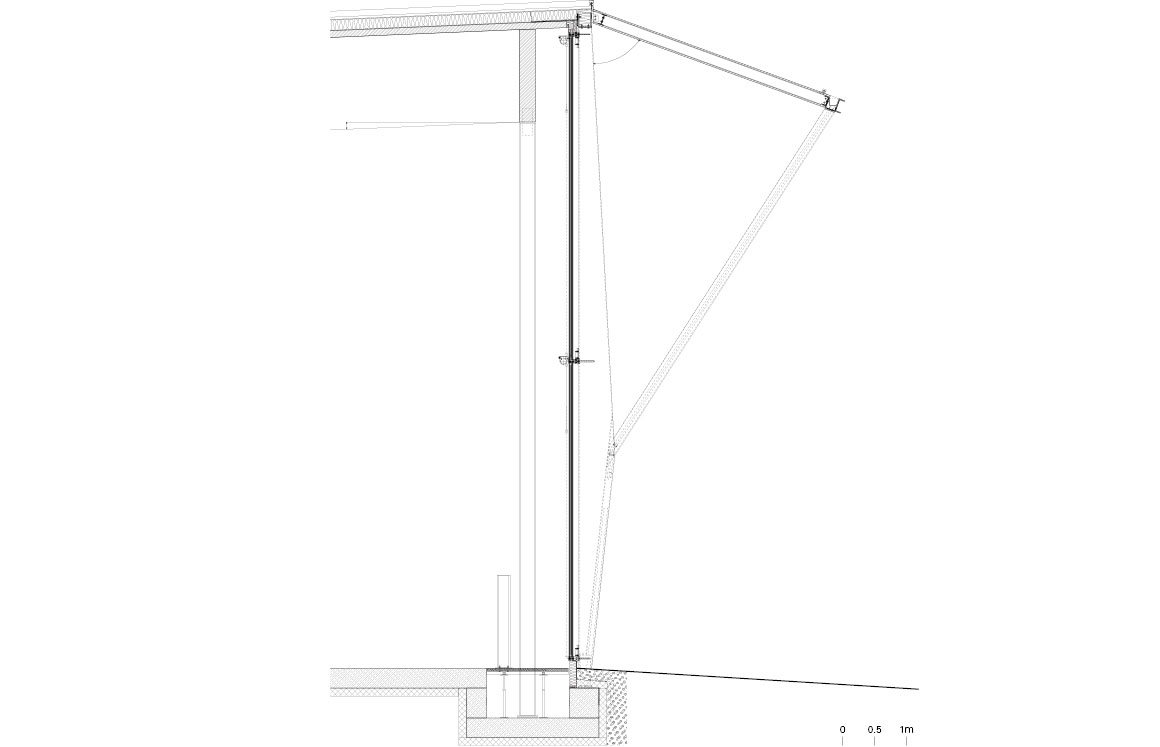

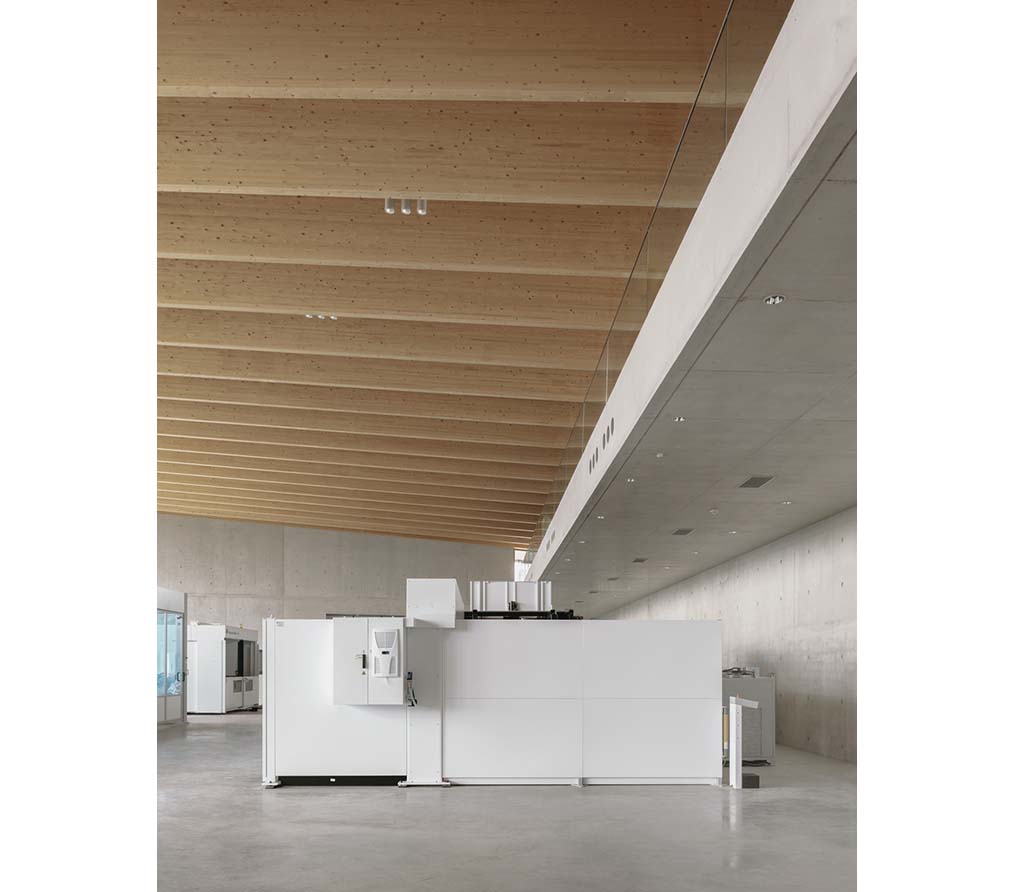

Another defining feature of this smart factory is its butterfly-shaped wooden roof. Sloped to direct rainwater into the courtyard, the roof also functions as a sunshade and incorporates varying lengths and angles in its folded design, adding structural and aesthetic dynamism. The roof is supported by 20-meter-long radial timber beams that are exposed throughout the interior, creating a warm and textured ceiling structure. These beams are divided into three structural systems corresponding to the exhibition hall, courtyard, and office areas. The grooves between the beams serve as spaces for lighting fixtures while also acting as sound absorbers.

The southern façade is clad in steel panels, complemented by large openings framed in locally sourced larch wood, which allow ample light into the exhibition hall and enhance the connection between interior and exterior environments. The metal corrugated exterior panels, which vary in size based on the location of the exhibition and office areas, reflect the industrial aesthetic while providing durability and low-maintenance benefits.

The Trumpf Hungary Smart Factory embodies the spirit of innovation and industrial progress. By integrating digital networks, advanced production technologies, and sustainability, it presents a vision of future industrial architecture. At the same time, it reflects its dual role as a factory and showroom through an architectural language that combines the warmth of wood with the precision of industry.

Project: Trumpf Hungary Smart Factory / Location: Gödöllö, Hungary / Architect(s): Barkow Leibinger/Frank Barkow, Regine Leibinger / Project team: Heiko Krech (Principal), Christian Coburger (Project Architect), Kate Bilyk, Zsofia Mester, Ina Reinecke, Ana Skrebic, Tereza Spindlerova, Annette Wagner / Architect of Record/Tendering/Construction Management: Óbuda Group, Budapest, Hungary / General Contractor: Strabag Építőipari Zrt., Budapest, Hungary / Structural Engineer: Óbuda Group, Budapest, Hungary / Climate/Energy Design: Óbuda Group, Budapest, Hungary / HVAC: PPR Plan Kft., Budapest, Hungary / Electrical Engineer: Hungaroproject Mérnöki. Kft., Budapest, Hungary / Fire Protection Consultant: Rein-R Éptüz Kft., Budapest, Hungary / Façade Consultant: Knippers Helbig, Berlin, Germany / Lighting Design: LICHTLICHT studio dinnebier, Berlin, Germany / Landscape Architect: Vár-Kert Mūsz. Tervezésl Kft., Budapest, Hungary / Client: TRUMPF Hungary Kft., Gödöllö, Hungary / Program: Showroom, Smart Factory, Event Space, Offices, Meeting Rooms, Cafeteria / Area: 5300m² / Construction: 2021.6~2023.2 / Completion: 2023 / Photograph: ©Simon Menges, Berlin, ©Barkow Leibinger (courtesy of the architect)