Full-scale prototype cabin built using waste wood and 3D printed concrete structure

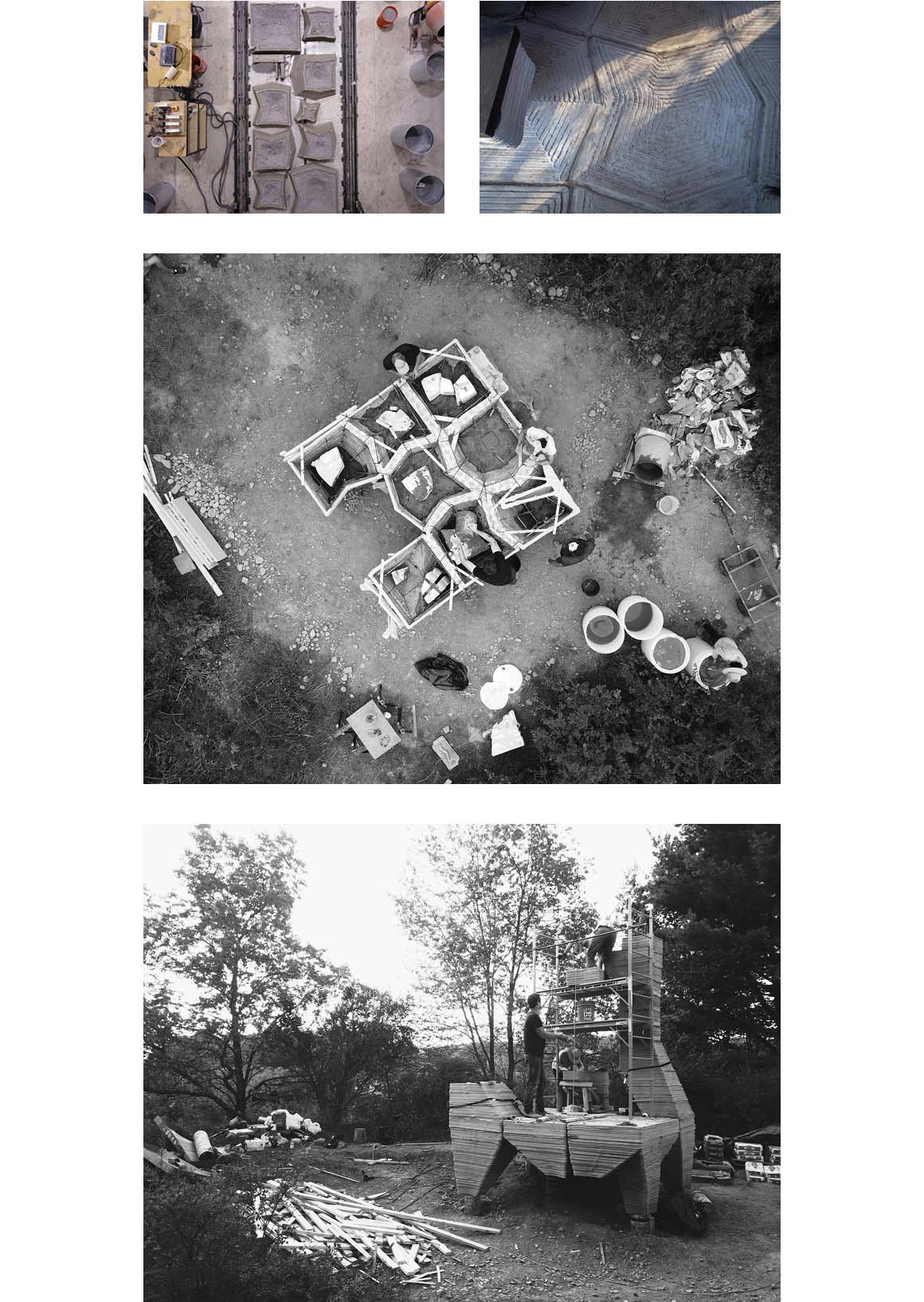

Ashen Cabin is a small building, 3D printed from concrete and clothed in a robotically fabricated envelope made of irregular ash wood logs by HANNAH, the design firm established by Leslie Lok and Sasa Zivkovic of Cornell AAP faculty. From the ground up, experimental digital design and fabrication technologies are intrinsic to the making of this architectural prototype, facilitating fundamentally new material methods, tectonic articulations, forms of construction, and architectural design languages.

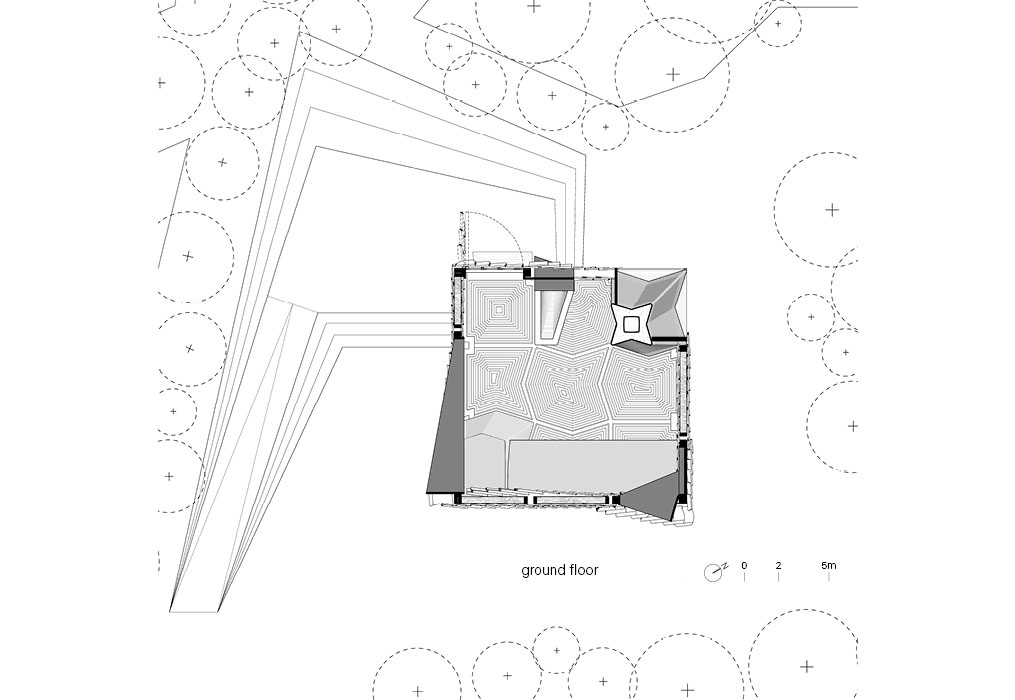

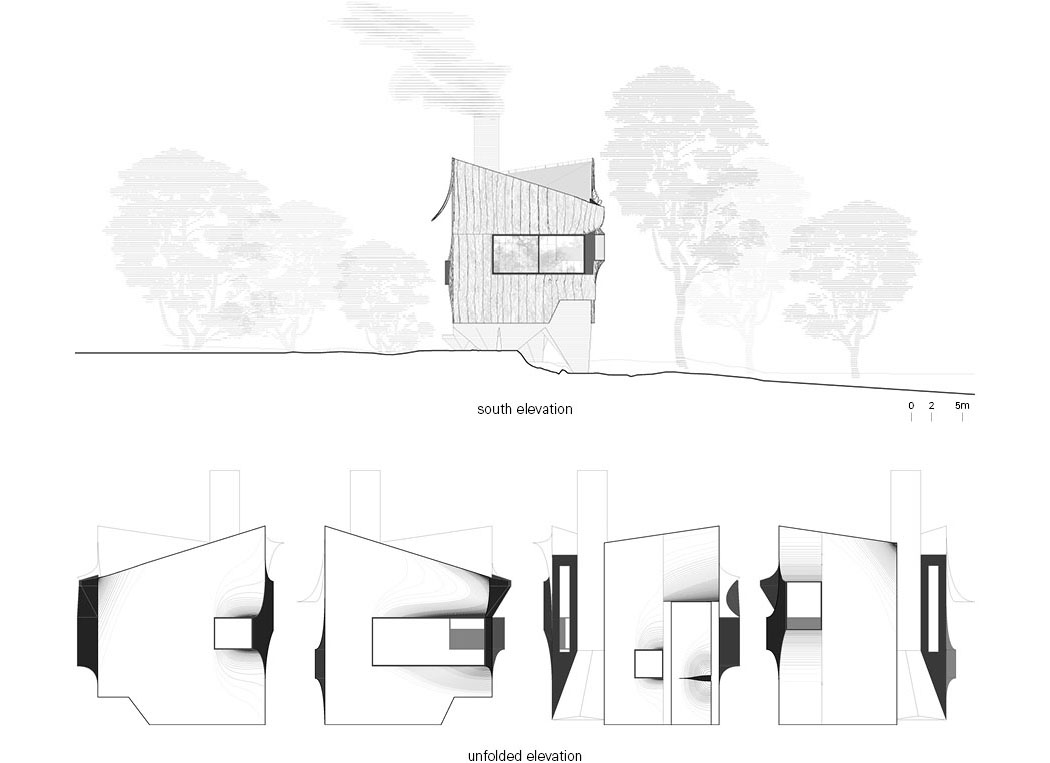

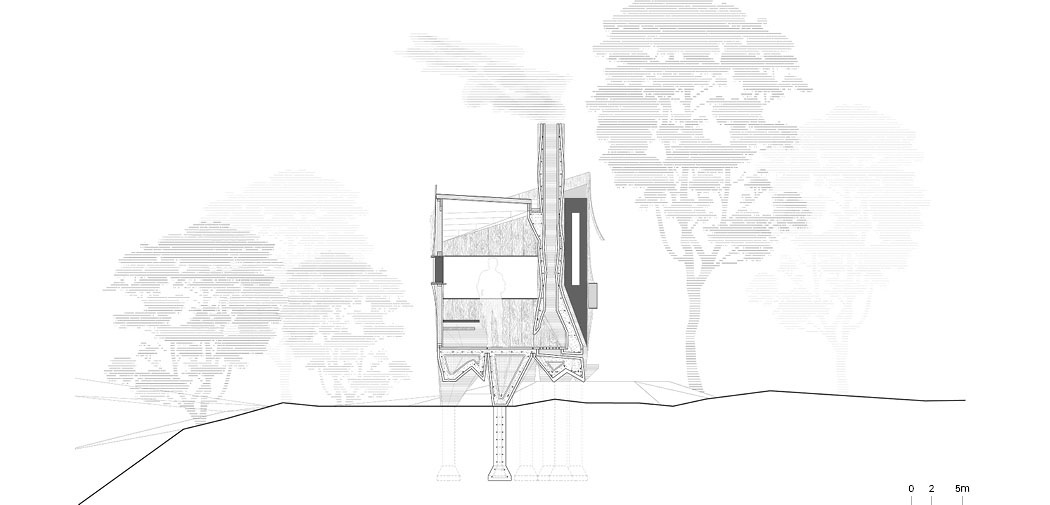

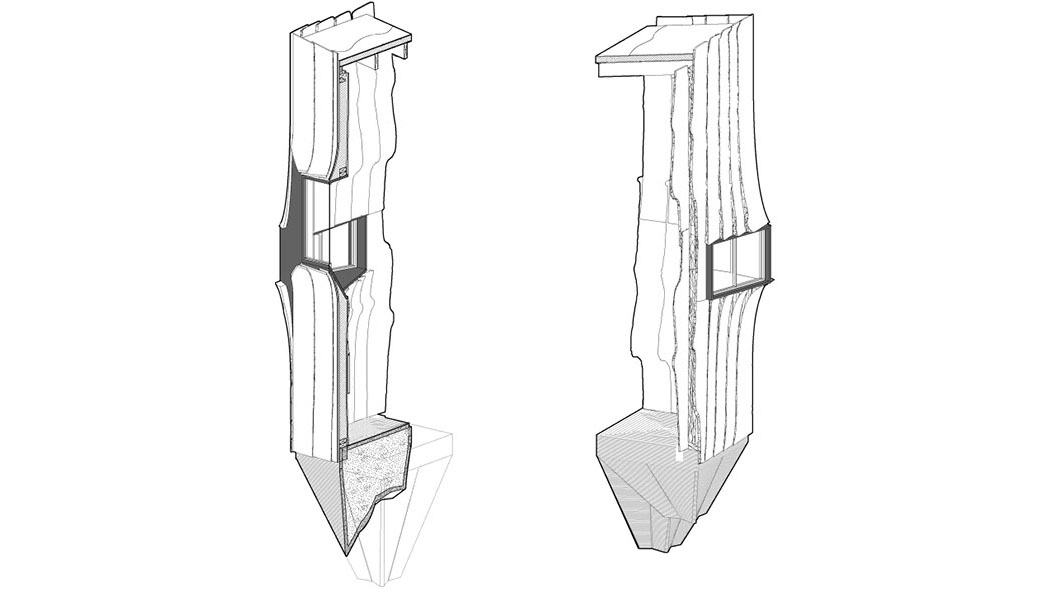

The cabin has a footprint of 9m2 and lifts off the ground on 3D printed, legs which adjust to the sloped terrain. All concrete components were fabricated on a self-built large-scale 3D printer. The concrete structure is characterized by three programmatic areas, a table, a storage seat element, and a 6.5m tall working fireplace. The project aims to reveal 3D printing’s idiosyncratic tectonic language by exploring how the layering of concrete, the relentless three-dimensional deposition of extruded lines of material, and the act of corbelling can suggest new strategies for building and form-making. Corbelling becomes an expressive and functional motif to highlight moments of programmatic significance throughout the concrete structure.

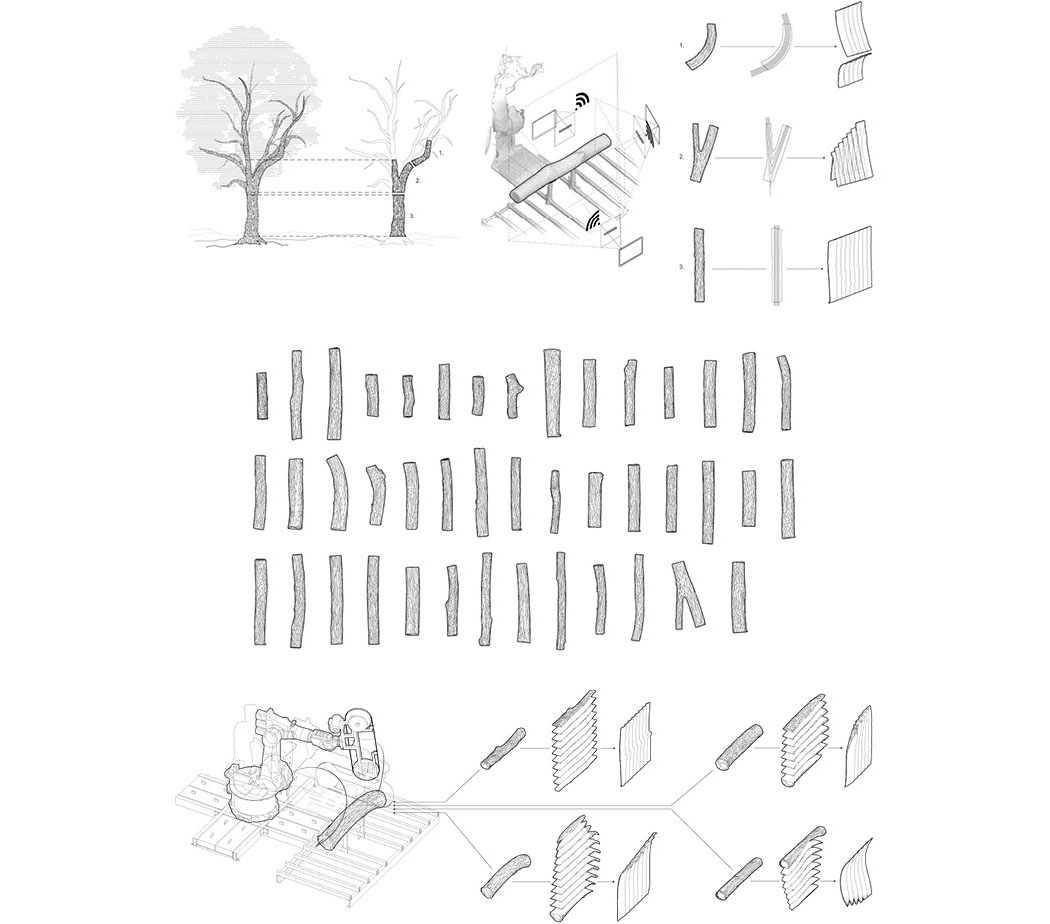

Ashen Cabin challenges preconceived notions about material standards in wood. The cabin utilizes wood infested by the Emerald Ash Borer for its envelope which, unfortunately, is widely considered as ‘waste’ by traditional sawmills and is unsuitable for construction due to its challenging geometries. By implementing high precision 3D scanning and robotic based fabrication technology, HANNAH upcycle this ‘waste wood’ into an abundantly available, affordable, and sustainable building material.

Infested ash trees often either decompose or are burned for energy. Unfortunately, both scenarios release CO2 into the atmosphere, and so the advantage to using compromised ash for construction is that is that it both binds the carbon to the earth and offsets the harvesting of more commonly used wood species.

In response to the use of concrete, the researchers developed a sustainable new full-scale 3D printing system. Concrete is responsible for 8% of total CO2 emissions. By using 3D printing, they eliminate the use of wasteful formwork and can deposit concrete smartly and only where structurally necessary, reducing its use considerably while also maintaining a building’s integrity.”

Architecturally, Ashen Cabin walks the line between familiar and unfamiliar, between technologically advanced and formally elemental. The curvature of the wood is strategically deployed to highlight moments of architectural importance such as windows, entrances, roofs, canopies, or provide additional programmatic opportunities such as integrated shelving, desk space, or storage. By addressing the complex realities of building and construction, the project explores the architectural opportunities inherent in the use of new construction techniques. Informed by making, Ashen Cabin tests new forms of construction and develops unfamiliar architectural languages, while responding to the environmental crisis.

Project: Ashen Cabin / Location: Ithaca, NY, USA / Architect: HANNAH / Principal architects: Leslie Lok and Sasa Zivkovic / Project team: concrete – Christopher Battaglia, Jeremy Bilotti, Elie Boutros, Reuben Chen, Justin Hazelwood, Mitchie Qiao; wood fabrication and design – Byungchan Ahn, Alexander Terry / Assembly and documentation team: concrete – Alexandre Mecattaf, Ethan Davis, Russell Southard, Dax Simitch Warke, Ramses Gonzales, Wangda Zhu; wood – Freddo Daneshvaran, Ramses Gonzalez, Jiaying Wei, Jiayi Xing, Xiaohang Yan, Sarah Elizabeth Bujnowski, Eleanor Jane Krause, Todd Petrie, Isabel Lucia Branas Jarque, Xiaoxue Ma / Wood studies: Xiaoxue Ma, Alexandre Mecattaf / Representation team: Byungchan Ahn, Kun Bi, Brian Havener, Lingzhe Lu / Cornell Arnot Teaching and Research Forest: Peter Smallidge (Arnot Forest Director) / Project realized with scientific support from the Cornell Robotic Construction Laboratory (RCL) / Sponsors: AAP College of Architecture, Art, and Planning; AAP Department of Architecture; HY-Flex Corporation; Cornell Atkinson Center for a Sustainable Future, Cornell Arnot Teaching and Research Forest / Special thanks to: Andrea Simitch and Val Warke / Complettion: 2019 / Photograph: ©Andy Chen (courtesy of the architect), ©Reuben Chen (courtesy of the architect), ©HANNAH