Kiln Tower for the Brickworks Museum

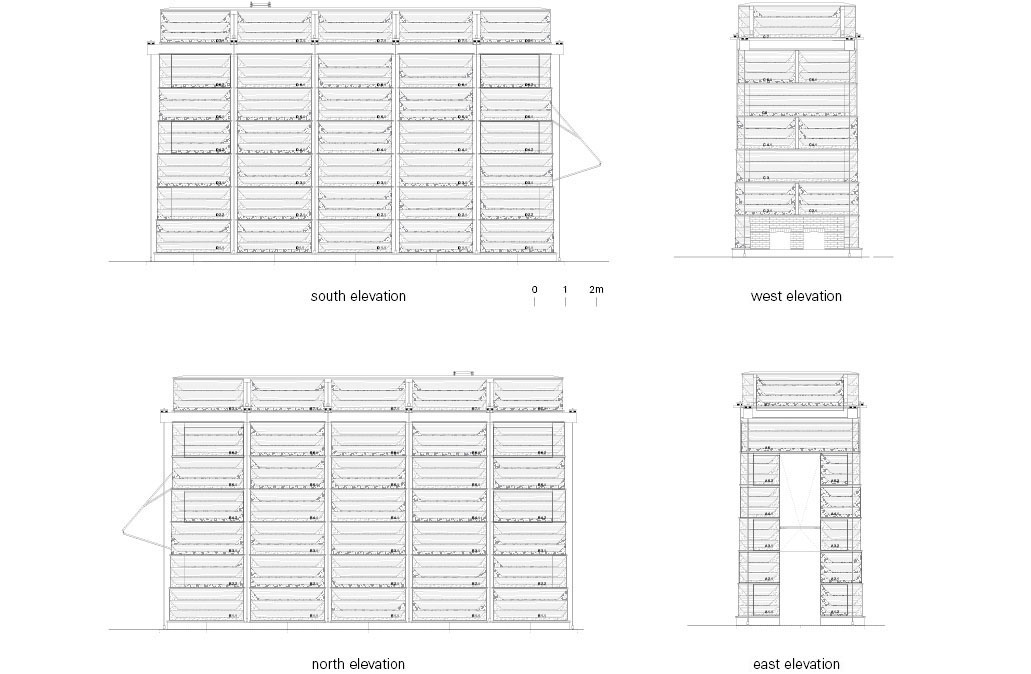

One of the most representative heritages of the small German-speaking Swiss town of Cham is its rammed earth buildings. The only surviving earthen brick building is now home to a Brickworks Museum. Alongside the museum, which was built on the site of a burned-out barn, stands a 10-meter high clay kiln tower. This tower is part of a complex that includes a no longer operational wood brick-drying shed and kiln, clay pits, and a residential building with gardens. Starting at 4 meters wide and 13 meters deep at the bottom and narrowing slightly towards the top, the tower doubles as a brick kiln and an observation deck on the roof above the staircase.

The project, involving around 30 students from the 2019 ETH Zürich summer school, follows a kiln tower built by the Technical University of Munich in 2017. The material used is unfired clay. While the traditional building method of stacking clay is common in Switzerland, the kiln tower is prefabricated, as evidenced by the seams between the blocks. This modern approach increases the efficiency and stability of rammed earth construction.

A new method applied Is prestressing, which involves putting pressure on the earthen walls to withstand seismic loads. This is achieved by adding high-tensile steel between the earthen walls that only resist compressive loads. The wooden trusses, connected to the roof beams to form a solid plate, ensure that the tensile forces are evenly transferred to the vertical walls. Steel bars extending from the ceiling are anchored to the concrete floor to close the gap with the walls and protect the ground. The incorporation of wooden floor plates into the wall structure is also unconventional. Each block is supported by a wooden plate, and the corners between the two materials are reinforced with trass lime to prevent erosion.

The tower must be completely dismantled after ten years, making recyclable clay the ideal material to meet this requirement. The prestressed structure is designed for easy disassembly, resulting in up to a 40% reduction in energy consumption compared to traditional construction techniques. Beyond being a natural material, this project showcases an opportunity to explore and enhance the inherent potential of earthen construction for improved performance.

Project: Kiln Tower for the Brickworks Museum / Location: Ziegelhütte, 6332 Cham, Switzerland / Architects: Boltshauser Architekten / Design team: Regina Pötzinger, Robert Gentner – students from TU Munich and ETH Zurich / Constructor: LEHMAG collaboration with students from various universities / Brick masonry:Terrabloc / Material: Ziegelei Schumacher / Structural engineer: SEFORB Sarl, Uster, Jörg Habenberger / Timber & metal: Nüssli / Lighting consultant: Reflexion / Prestressing engineering: Jakob / Foundation: Keller Unternehmungen / Civil engineer: KIBAG Holding / Master builder: Ineichen / Client: Verein Ofenturm Ziegelei-Museum, Cham / Use: viewing tower, store-room, kiln / Gross floor area: 60m² / Building volume: 480m³ / Design: 2017~2019.7. / Construction: 2021.3. / Photograph: ⓒKuster Frey (courtesy of the architect)

[powerkit_separator style=”double” height=”5″]